Rail Industry

Rolls-Royce has officially opened a redesigned and upgraded facility in Cape Town, South Africa, where 232 MTU engines destined for rail will be assembled, tested, painted and commissioned.

Rolls-Royce has invested about R50-million (£3 million)in upgrading and revamping the facility to be able to localise the manufacturing of the engines. MTU South Africa is a subsidiary of MTU Friedrichshafen, the core business of Rolls-Royce Power Systems, a division of Rolls-Royce plc.

The MTU brand develop and produce large high-speed engines and propulsion systems for ships and heavy land, rail and defence vehicles, as well as drive systems for use in the oil and gas industry and in power generation. Our diesel engines and gas engines are capable of power outputs up to 10,000 kW and 2,535 kW respectively. MTU also supplies customized electronic automation and control units for its engines and propulsion systems.

The deal for the 232 engines is one of the largest rail orders in MTU’s history.

Rolls-Royce will supply the 20-cylinder Series 4000 R63L model engines, with a power output of 3 300 kW, to the China Railway Rolling Stock Corporation (CRRC), which will manufacture the locomotives. The Class 45 locomotives will then be delivered by CRRC to the TFR.

“This is a big moment for South Africa. We are very proud to be the manufacturer within this huge Transnet procurement process. We have a clear vision to make a positive difference through better power for a changing Africa,” said MTU South Africa CEO Andrea Nono.

Speaking at the launch of the upgraded facility, in Montague Gardens, Cape Town, Nono said that the company would take on an additional 20 people for the project, which has also established a new training centre where intensive training for staff at MTU South Africa has been provided.

Employees were also sent to the MTU head office in Friedrichshafen, Germany, for skills transfer training courses that lasted two months. This helped employees gain practical experience in assembling, painting and testing the engines.

Nono said the engines were state-of-the-art and extremely powerful, but fuel-efficient at the same time.

“Picture eight Ferraris. That would give a similar output to one of our engines, although [our engines] are more condensed and fuel-efficient,” Nono told the launch.

She told Engineering News Online that the new facility was a significant move for MTU South Africa, which is celebrating its fifteenth anniversary this year. Prior to the Transnet order, the company serviced customers mainly in the mining and marine sectors.

“Our whole business model has changed in South Africa. We were a sales and service company for Rolls-Royce products, but now we are adding a whole new layer,” said Nono.

She added that MTU saw itself as an active partner in the further development of South Africa’s manufacturing industry.

Meanwhile, MTU industrial business VP Bernd Kruper noted that the company had plans to expand into sub-Saharan Africa.

“Africa is an extremely interesting market for us and one in which we see enormous growth potential. We regard the upgrading of our facility in Cape Town as an important strategic step towards deepening our partnership with customers in Africa,” he said.

The MTU facility has been upgraded in various ways. For instance, a new ultramodern paint booth, designed to use environment-friendly paints, has been installed. The revamping also includes the upgrading of the test bench, the assembly and logistics areas, as well as the acquisition of new overhead cranes.

White Knight are proud to supply trackside lighting to the rail industry. Call us on 023 9266 8624 for all your signalling and bardic lamp requirements.

White Knight have been manufacturing Network Rail approved signalling lamps for over 25 years.

One of the major train operating companies (TOC) was concerned that the weight of the train driver’s bag was becoming a health and safety issue. This was partly due to the weight of the original bardic lamps that train drivers carried.

White Knight responded by designing and producing the hugely successful Halo personal signalling lamp. Not only was it significantly lighter than the original Bardic lamp, it was also much brighter.

The Halo range of hand-held signal lamp is approved by Network Rail (Cert. No. PA/05/965) and still widely used and trusted within the rail industry.

The Halo range includes:

Halo Plus2™ Personal Signalling Lamps

The HP-11 range of Personal Signalling Lamps features the latest advances in LED Technology. Each lamp features a high performance super bright LED array in up to three colour combinations – red, amber and green. All colours conform to BS 1376 signal colours. Other specialist colour requirements available on request.

HP-11R3RT –White halogen torch incorporating Red / Amber / Green LED signal lamps

HP-11R3 –White halogen torch incorporating Red / Amber / Green LED signal lamps

HP-11R2 – White halogen torch incorporating Red / Green LED signal lamps

HP-11R – White halogen torch incorporating a Red LED signal lamp

Personal Rechargeable Hand Lamps

Halo Plus2™ Torch – Industry standard rechargeable halogen torches providing a light-weight compact hand held lighting solution.

WK5 Hand Lamp – Professional halogen rechargeable hand lamps that are powerful, rugged and versatile, giving years of reliable and trouble free service.

White Knight is best known for its range of rechargeable handlamps. The ‘White Knight’ range was developed after extensive research. The Halo Plus torch is Network Rail approved, and the Halo Plus 2 lamp has been in production since 1990. It is used by the British, German and Swiss rail networks, as well as the Eurostar service and infrastructure companies.

White Knight is currently a market leader in the supply of specialised lamps to “Blue Light Services”, Rail Networks, Military and Public Utilities worldwide. White Knight holds BS EN ISO 9001 certification, and the company has also achieved a range of industry standards and certification.

Bespoke Product Design for Rail and Emergency Services

From time to time there will be a request from clients to design and develop bespoke lighting products for a specific industry or application.

These include :

WK Egg Candling Adapter – a portable rechargeable solution (230V or vehicle) is effective in illuminating eggs for disease detection and is simplicity itself to set up and use. It has been in use by egg inspectors at the Department of the Environment, Food and Rural Affairs (DEFRA) for many years proving to be an unqualified success.

WK Egg Candling Adapter – a portable rechargeable solution (230V or vehicle) is effective in illuminating eggs for disease detection and is simplicity itself to set up and use. It has been in use by egg inspectors at the Department of the Environment, Food and Rural Affairs (DEFRA) for many years proving to be an unqualified success.

100 Watt Portable Flood Lamp Kit – Developed in conjunction with major police forces the ‘SL-50’ and ‘SL-501’ combination provides a powerful hand held white halogen floodlight kit for personal use. Ideal for SOC, Photography, Search, Accident Investigation and other situations.

100 Watt Portable Flood Lamp Kit – Developed in conjunction with major police forces the ‘SL-50’ and ‘SL-501’ combination provides a powerful hand held white halogen floodlight kit for personal use. Ideal for SOC, Photography, Search, Accident Investigation and other situations.

Conelight – a compact lightweight traffic cone beacon designed for use by all ‘blue light’ emergency services. Conelight uses the latest LED technology to provide outstanding performance and rapid dispersion. The brilliant flash is visible even in daylight. Designed to give improved stability in wind and passing traffic, the beacon uses its battery pack to provide the cone with an extremely low centre of gravity.

Conelight – a compact lightweight traffic cone beacon designed for use by all ‘blue light’ emergency services. Conelight uses the latest LED technology to provide outstanding performance and rapid dispersion. The brilliant flash is visible even in daylight. Designed to give improved stability in wind and passing traffic, the beacon uses its battery pack to provide the cone with an extremely low centre of gravity.

Talk to White Knight if you have a specific need for portable lighting within your industry. Call +44 (0)23 9266 8624

As the Seinne subsides and Paris gets back to normal, one of its biggest ever rail projects gets under way.

The €25bn Grand Paris Express metro began on June 4 with a ground-breaking ceremony at the site of the future Fort d’Issy-Vanves-Clamart station.

The first phase of the project, Line 15 South, will see 16 stations linking the southern suburbs of Paris. This phase is scheduled for completion in 2022 at a cost of €5.7bn. The project is being overseen by Société du Grand Paris (SGP), who will be co-ordinating over 1500 engineering experts.

The new Grand Paris Express Line 15 should see over 200km of new line and 68 new stations. There will be trains of 2.80m wide and 108m long travelling at speeds of up to 120 kph. It is anticipated that the new 33km line will carry about 300,000 passengers every day with a projected morning rush of up to 34 560 passengers per hour.

This project is technically challenging, and will do much to ease the economic, social and cultural issues that are caused by the current public transport limitations.

Plans drawn up in January 1945 have been found in an archive of historical documents. These plans were discovered by engineers working on the design of the proposed Visitors Centre at the Forth Bridge.

Although the plan bears a resemblance to the Sydney Harbour Bridge which was built in 1932 it is almost 3 times bigger and features 110m arches and 70m masonry towers.

The drawing is attributed to the ‘Engineers Department Edinburgh’ and is dated 22 January 1945. The bridge was never built and the plans disappeared in obscurity which suggests that it might have been drawn up as a back-up plan in case the existing bridge was attacked and destroyed during World War II.

This is just speculation, and Network Rail, who own the Forth Bridge and VisitScotland are appealing for anyone with information about the plans to help solve the mystery.

Ian Heigh, a senior project manager for Network Rail, said: “To be honest, even Network Rail’s longest serving railway engineers seem to be a bit perplexed by the true purpose of these proposals. If this bridge had been built, the entire character of the area would have altered, not just the famous landmark. We’d love to know more about these plans, so I’d encourage anyone with more information to get in touch.” Any information can be sent to: info@forthbridgeexperience.com.

The Forth Bridge is now a world heritage site and the proposals for a visitor’s centre ‘The Forth Bridge Experience’ can be seen here.

According to an article in the Rail Tecnology Magazine “the railway across the north needs a “bigger, more expensive, and transformational” solution to fix its historical lack of investment, because what is committed now simply is not enough, rail bosses have said.”

According to an article in the Rail Tecnology Magazine “the railway across the north needs a “bigger, more expensive, and transformational” solution to fix its historical lack of investment, because what is committed now simply is not enough, rail bosses have said.”

The leaders of Transport for the North (TfN) and Northern Rail, David Brown and Alex Hynes, have agreed that, although the next 4 years will see the issue of under investment being addressed, it is still not enough to make all the changes required to make this one of the best regions in the world.

“At the moment, we have to compromise all the time,” Hynes added.

The Flying Scotsman has arrived triumphant in York.

A name that is instantly recognisable as one of the most famous steam trains in the world, The Flying Scotsman has now been restored to its former glory and taken up residence in the National Rail Museum in York.

The train left Kings Cross station on the morning of Thursday 25 February 2016, and arrived in York a 13:20.

On board, for this journey were 297 passengers, some of whom paid up to £450 for a ticket to travel on the train. Amongst the VIP guests was Ron Kennedy, an 83-year-old who drove the Flying Scotsman from 1956 until it was retired in 1963.

Crowds gathered at Kings Cross to see The Flying Scotsman leave London, and thousands more people lined the route all the way to York. There were a couple of incidents where excited trainspotters on the track forced the train to slow down, and one poor soul who waited to film the train as it went by, had his view obliterated by an unfortunately timed Virgin train going in the opposite direction.

History of the Flying Scotsman

Locomotive No. 1472 Flying Scotsman was designed by Sir Nigel Gresly, and built for London and North Eastern Railway (LNER) at Doncaster Works in 1923. In 1924 it was selected to appear at the British Empire Exhibition in London, and was renumbered 4472, and given the name ‘Flying Scotsman’ after the London to Edinburgh route that it covered.

The Flying Scotsman set a world speed record in 1934 when it became the first train to officially reach a speed of 100 mph. It remained in service on the Edinburgh to London service until 1963 when it was retired. In its career, the Flying Scotsman had clocked up an impressive 3,341,000 km. After retirement the train spent time in the USA and in Australia where it set the record for the longest non-stop run by a steam locomotive when it ran 711 km in August 1989.

The Flying Scotsman is 21m long, weighs about 96 tonnes and has a top speed of 100mph. It was bought by the National Railway Museum (NRM) in 2004, using £415,000 in public donations, a £365,000 gift from Sir Richard Branson and a £1.8m grant from the National Heritage Memorial Fund. The restoration cost £4.2m, and took 10 years to complete.

The Flying Scotsman is currently on show at the National Railway Museum from 26 February until 7 March and again from 25 March and 8 May. Find out more about seeing this magnificent locomotive

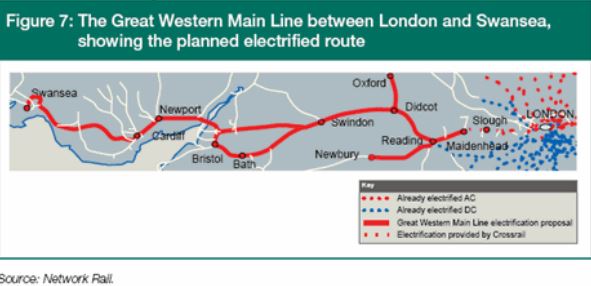

Great Western Main Line will see its electrification programme rolled out on the following dates:

- Maidenhead to Didcot – December 2017

- Didcot to Wootton Bassett Junction – December 2018

- Wootton Bassett Junction to Bristol Parkway – December 2018

- Reading to Newbury – December 2018

- Bristol Parkway to Cardiff – December 2018

- Didcot to Oxford – June 2019

- Wootton Bassett Junction to Bristol Temple Meads – February 2019-April 2020

This update comes after numerous set-backs to the Great Western electrification scheme which have included poor productivity, inefficiency, design standard issues and increased costs.

Costs are currently estimated at between £2.5bn and £2.8bn, a far cry from the original £874m in 2012.

The Bristol Parkway to Cardiff works were originally scheduled for 2017 but are now set for completion by December 2018.

Find out more about this project from Great Western

A new programme of improvements for London’s Waterloo station has just been unveiled.

About 100 million people per year pass through Waterloo station, and it has had no major upgrades since the 1930s.

This project will see the strengthening of some bridges, and the extension of 4 platforms.

Planning permission has just been submitted, and the project is scheduled for completion at the end of 2016.

Find out more Wessex Capacity Improvement Programme

The Digital Future – a live debate on the role of digital technology in rail transport.

Sponsored by Siemens Mobility, this event will take place on Wednesday 9 September from12: – 13:00.

Listen to key speakers discuss some of the key issues facing the rail industry and join in the interactive debate.

Streamed live from London’s Tower Bridge Studio, this broadcast will feature the following speakers:

- David Horne | CEO – Virgin Trains East Coast

- Wim Fabries | Programme Director – ERTMS, Ministry of Infrastructure & Environment, Netherlands

- Jerry England | Group Director – Digital Railway, Network Rail

- Dr Jochen Eickholt | CEO – Siemens Mobility

The event will be moderated by Chris Jackson, Editor-in-Chief, Railway Gazette Group

The issues to be discussed are:

- What can digital technology offer in the search additional capacity as the demand for rail transport continues to increase? What is the role of communications-based train control and driver advisory systems?

- How might advanced train planning and traffic management systems help to improve operational performance and reliability?

- What degree of automation might be appropriate for main line railways, and what lessons can be gained from experience in the metro sector? Will ERTMS and CBTC converge in the next generation of train control systems?

- Where does the digital revolution open up opportunities to improve passenger information, journey planning and smart ticketing? How can railways meet customer demands to be constantly connected through Wi-Fi on trains, or the real-time tracking of freight consignments?

- What are the benefits of real-time monitoring and automation in the inspection and maintenance processes, for both trains and infrastructure?

- How will the introduction of advanced technology impact on safety? What are the human factors affecting drivers and train crew, or other staff?

- Can the railway sector attract and retain the skilled staff needed to develop, operate and maintain advanced technologies in the face of competition from other industries?

If you are interested in joining the debate then register here to listen to the presentations live and share the debate.